Home » Manufacturing Facility

Situated in the southern part of India, Shah Eye Care Pvt. Ltd. features a state-of-the-art manufacturing plant fully equipped with skilled personnel, cutting-edge machinery, and abundant resources. This facility is dedicated to the production of high-quality Ophthalmic Medical Device, serving the needs of the global market and its standards. Moreover our comprehensive manufacturing process encompasses raw material management to the production of finished goods ready for shipment to customers worldwide

Our dedicated stores meticulously handle imported raw materials, subjecting them to stringent incoming inspections and batch number tracking. Consequently, this ensures the integrity and traceability of components. Additionally, this practice is applicable to various Ophthalmic Medical Device production processes.

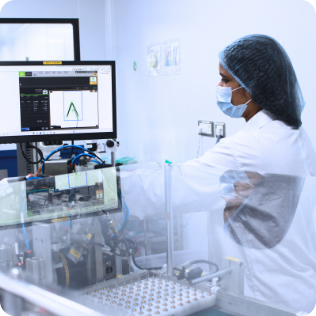

At Shah Eye Care, our manufacturing area spans 18,000 sq. ft., including a 6,000 sq. ft. ISO 7 cleanroom space. This setup is designed to meet the distinct requirements of various Ophthalmic Medical Device manufacturing standards.

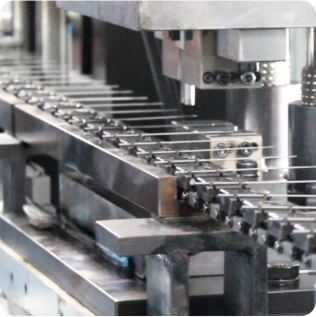

The production facility features automated and semi-automated lines encompassing flattening, coining, depth marking, and pre-notch procedures. These steps are followed by ultrasonic cleaning before and after to prepare the instruments for subsequent phases. The hardening and tempering stage ensures uniform strength and ductility,

We uphold the highest standards to deliver excellence in every aspect of our operations. Right from the beginning of the manufacturing process, our unwavering dedication ensures that our products meet and exceed quality benchmarks

Leveraging German technology, our Artificial Intelligence-based electro etching and polishing processes guarantee precision and unparalleled consistency. Furthermore, due to its precision and unique ability to extract minute particles during the process, the polishing results in a matte finish surface, featuring an anti-glare effect in Ophthalmic Medical Devices

Rigorous testing protocols are implemented at each stage to ensure the safety, efficacy, and reliability of our Ophthalmic Medical Devices. Additionally, we employ advanced testing methodologies to assess the functionality and performance of our devices.

The flexibility of our assembly space, equipped with Fully-Automated Special-Purpose Machines, tailors the production process to uphold the necessary quality standards. Utilizing a digital Technology further ensures the quality of knives for a wide array of Ophthalmic Medical Device.

Benefit from our meticulous packing procedures involving Tyvek packaging, organized boxes, and labeling, ensuring the secure transportation of products. The final touch involves ETO sterilization, guaranteeing the delivery of sterile Ophthalmic Medical Devices to our customers.

In the Finished Goods (FG) and Dispatch Area, completed products undergo quality checks before being organized, packaged, and labeled for shipment. This stage ensures that the finished goods are prepared efficiently for distribution, maintaining high standards of quality.

Utilizing our advanced facility, We are actively involved in manufacturing our own brands. Additionally, we offer our production facility for Private Labeling and contract manufacturing of Ophthalmic Medical Devices, ensuring QA & Regulatory.